Field Notes: A Tour of Mesobot’s Guts March 10, 2021

Dispatches from Bermuda

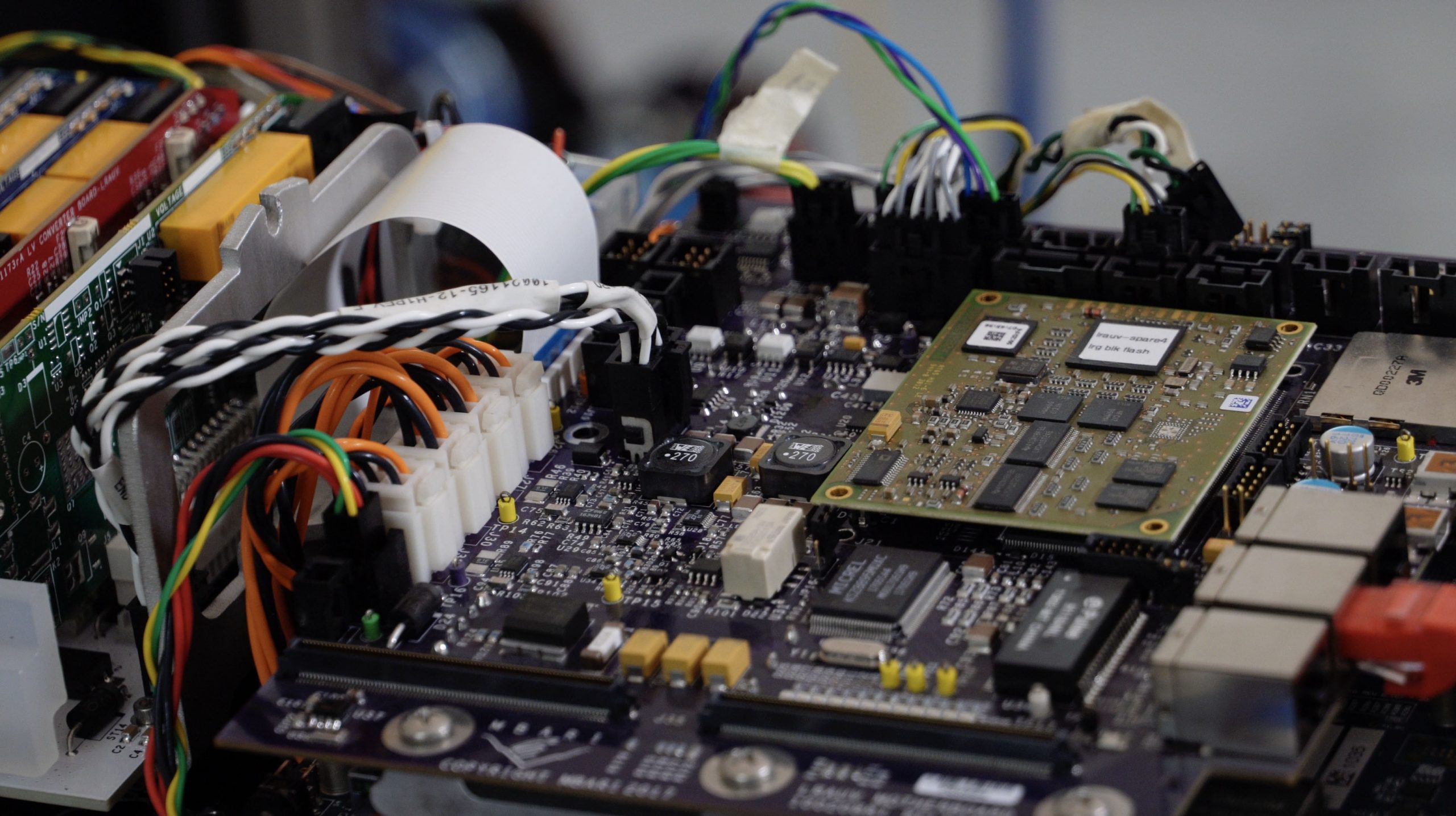

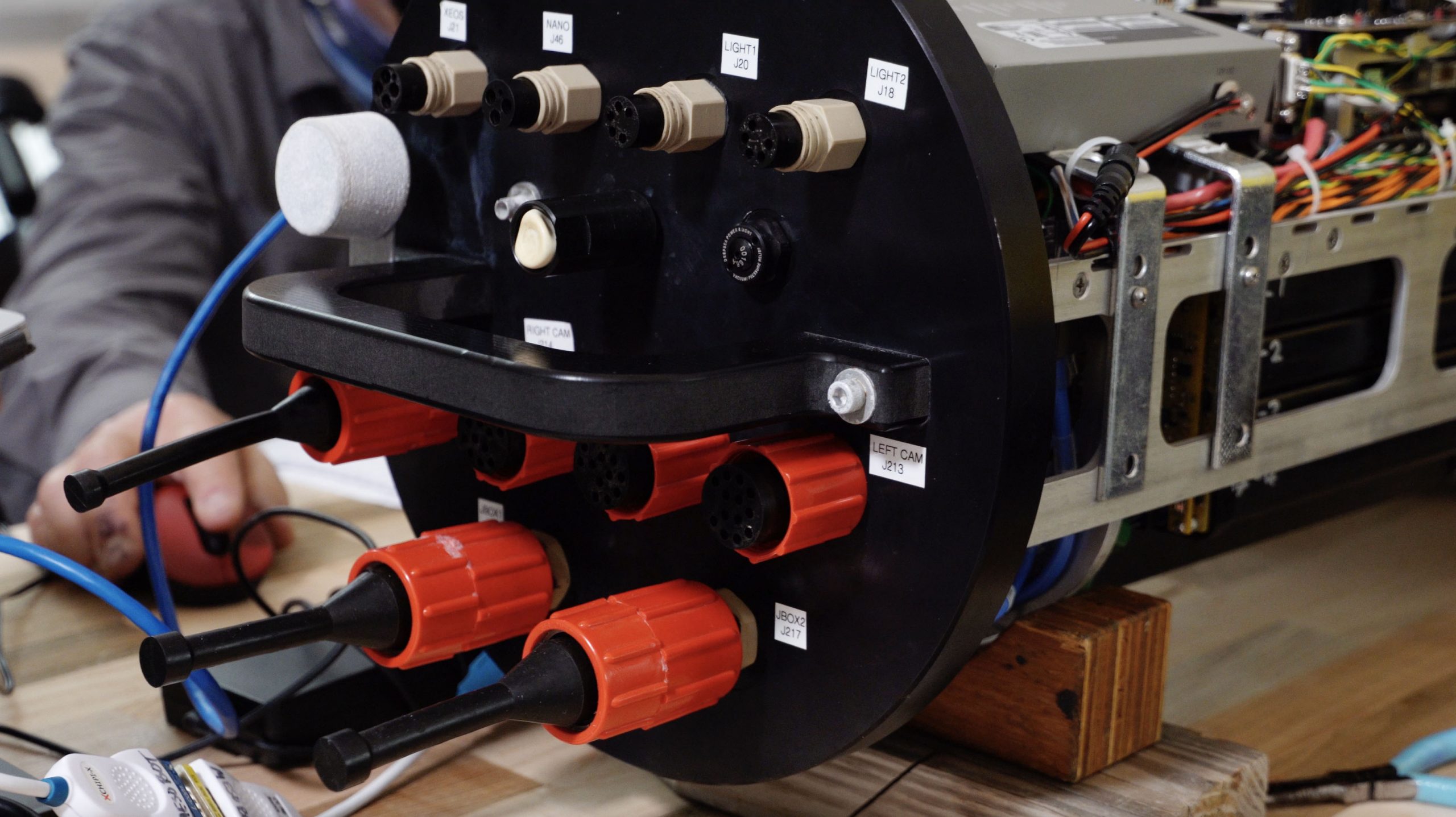

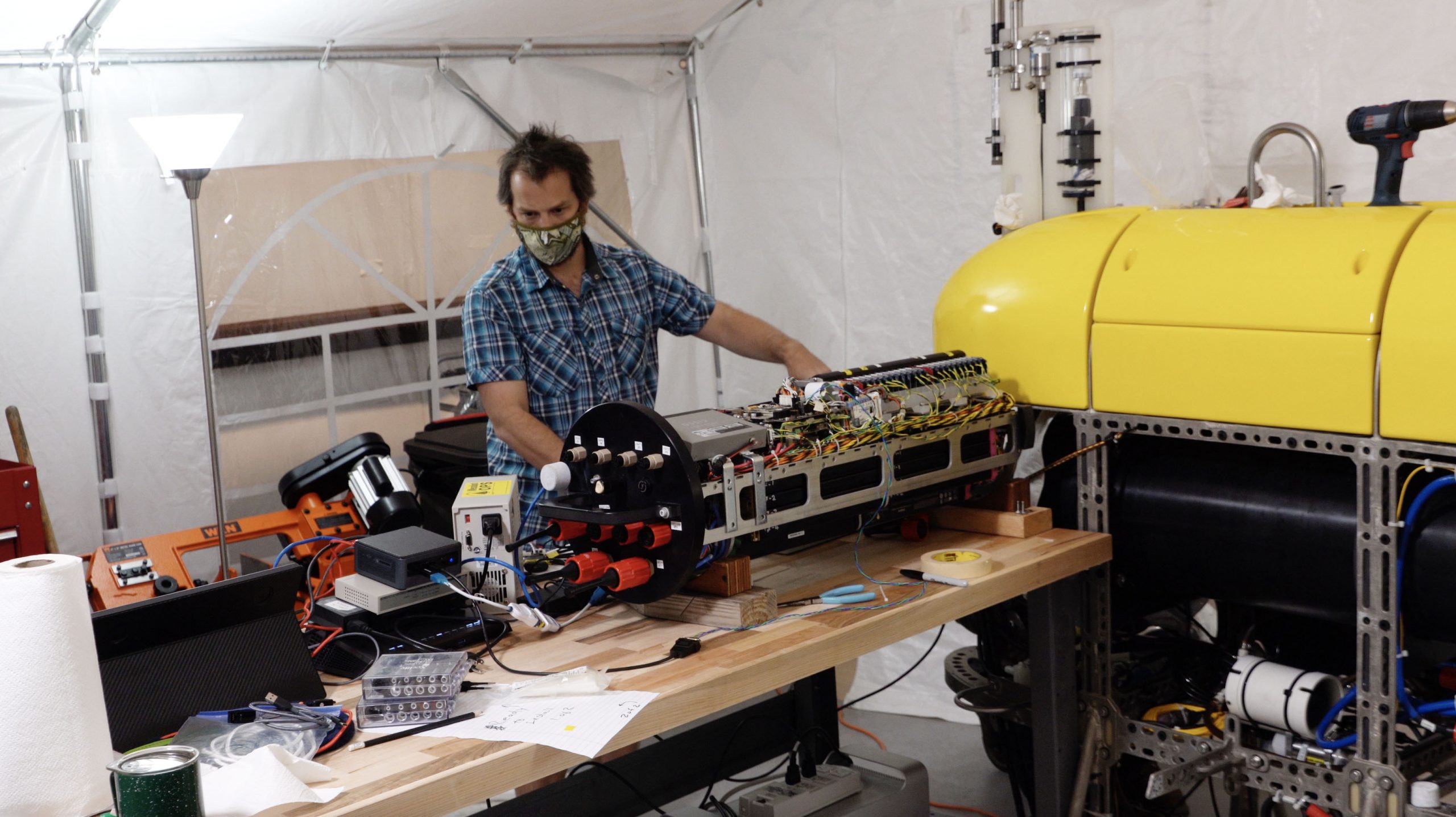

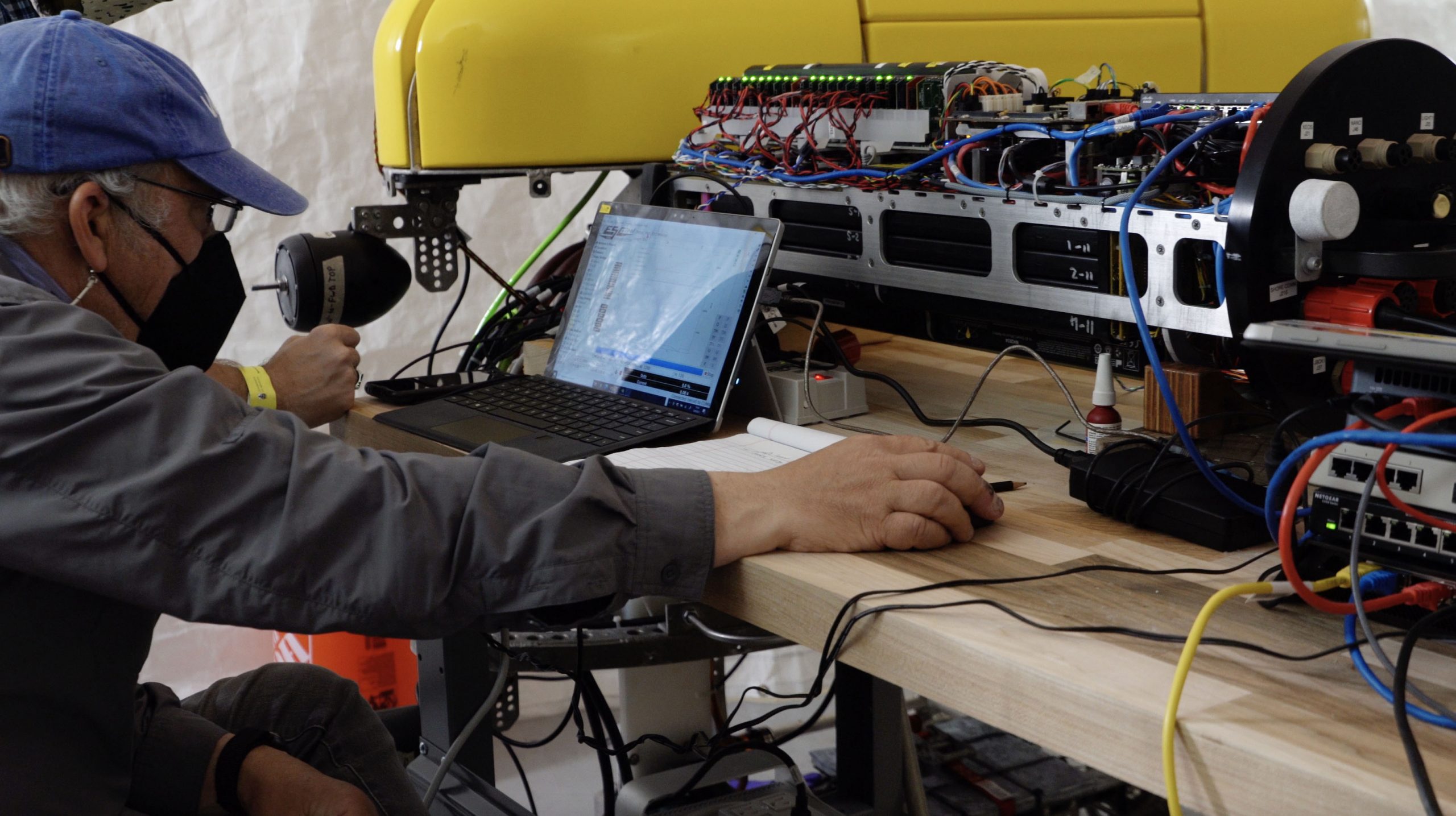

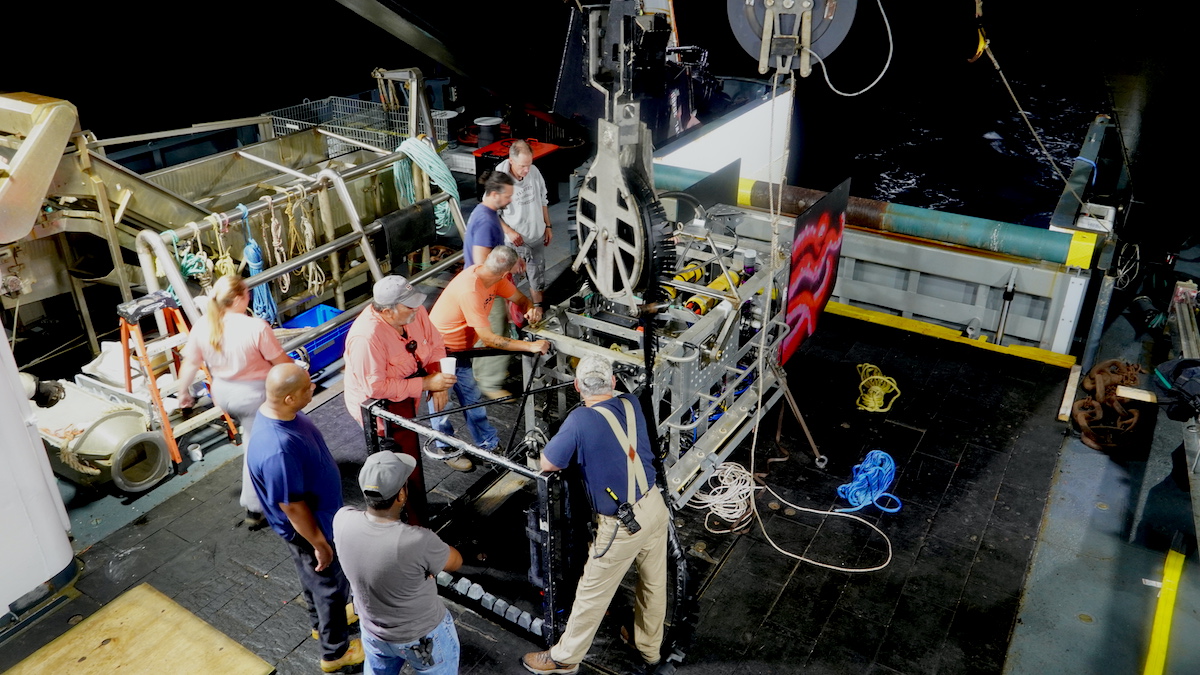

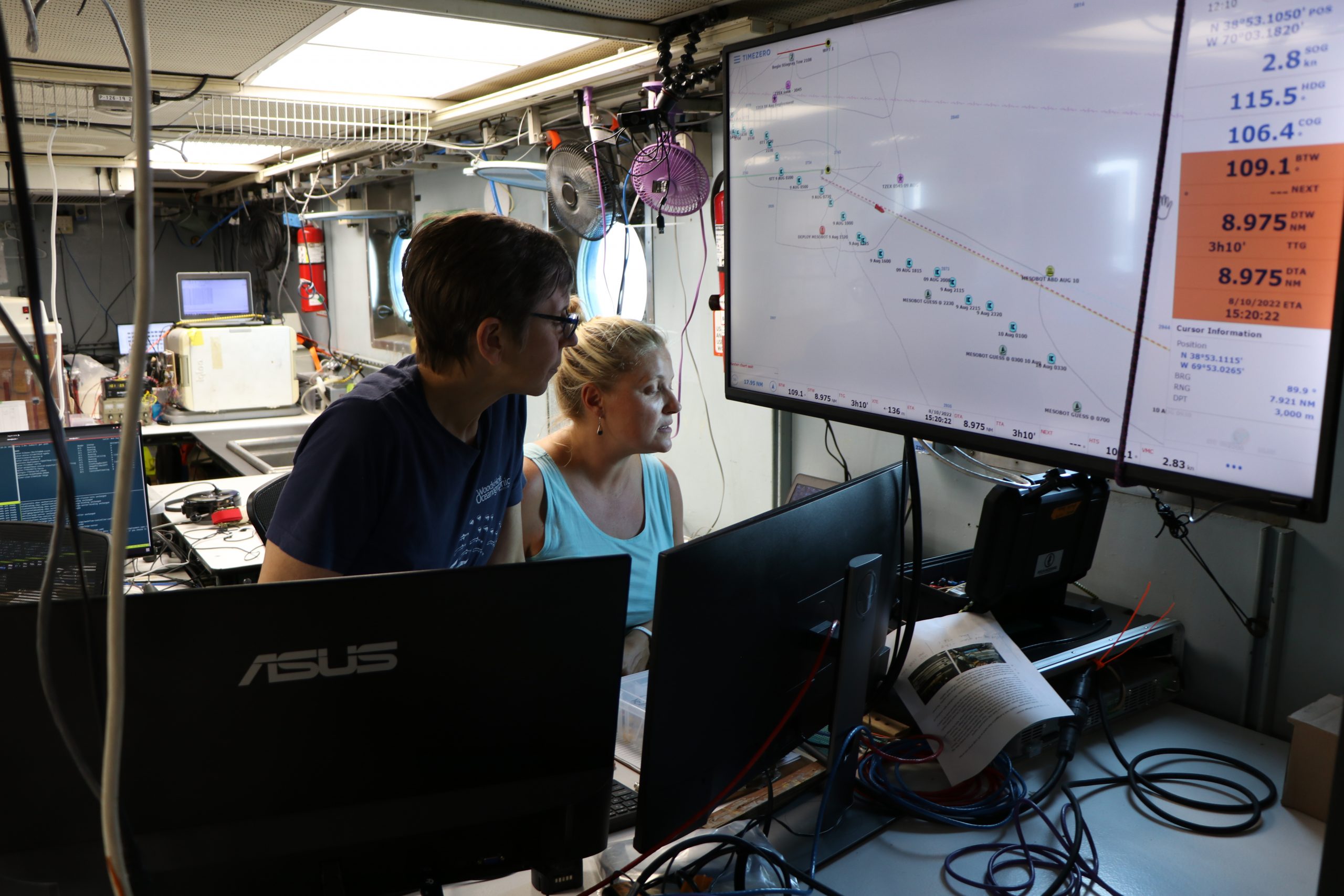

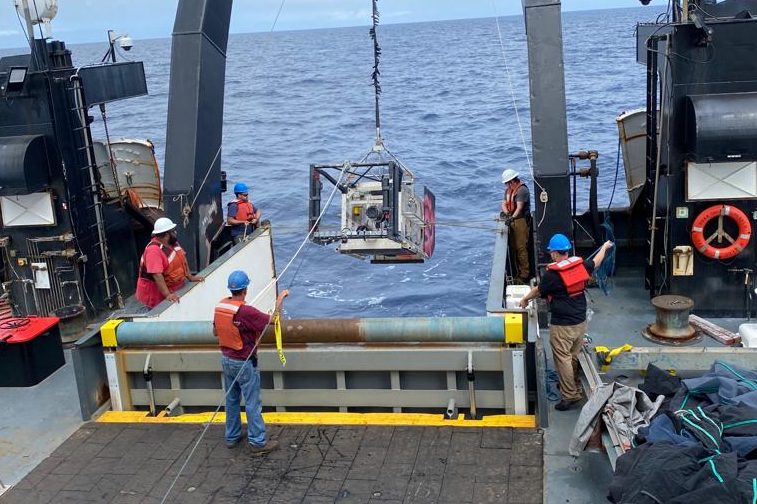

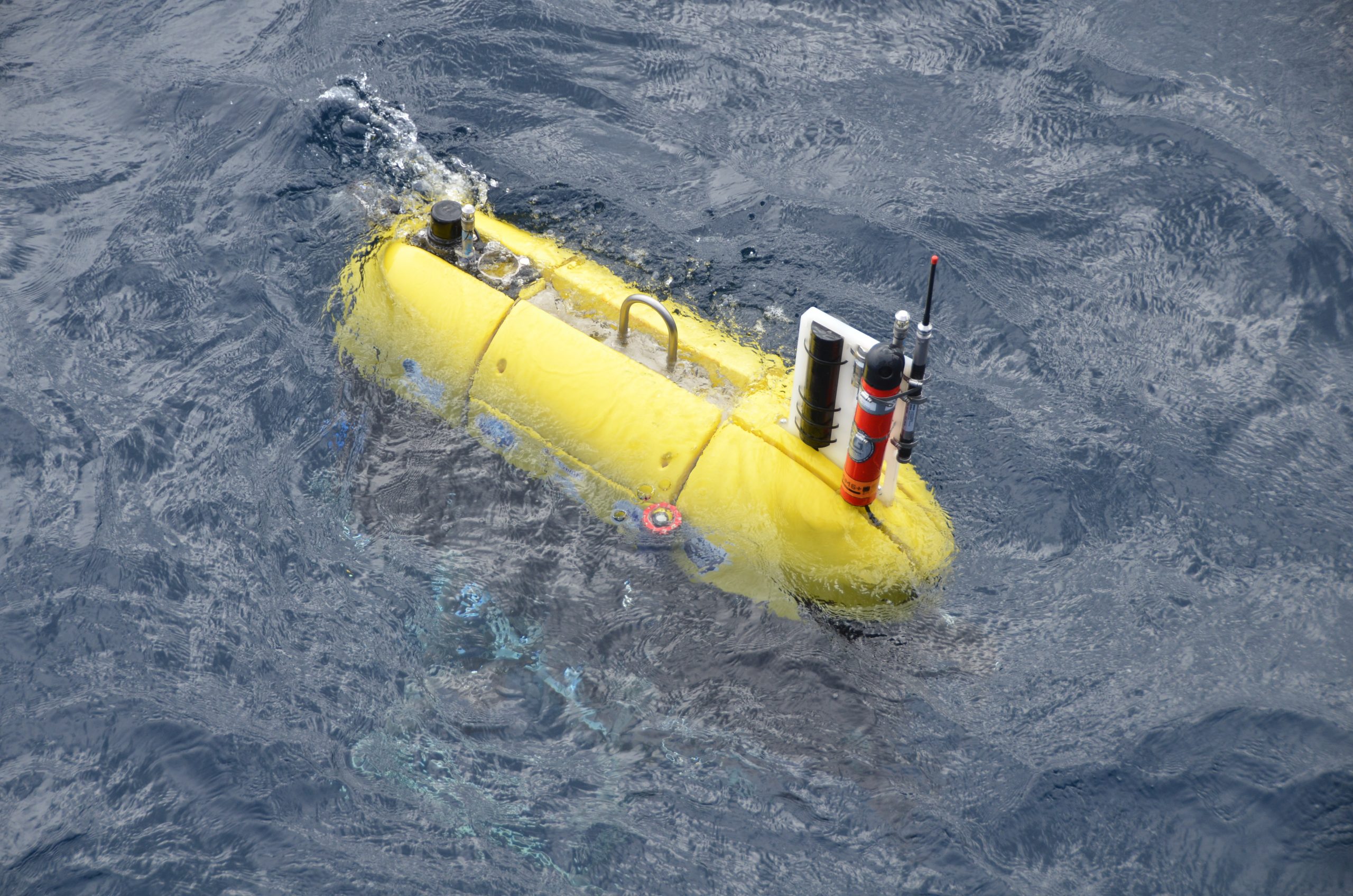

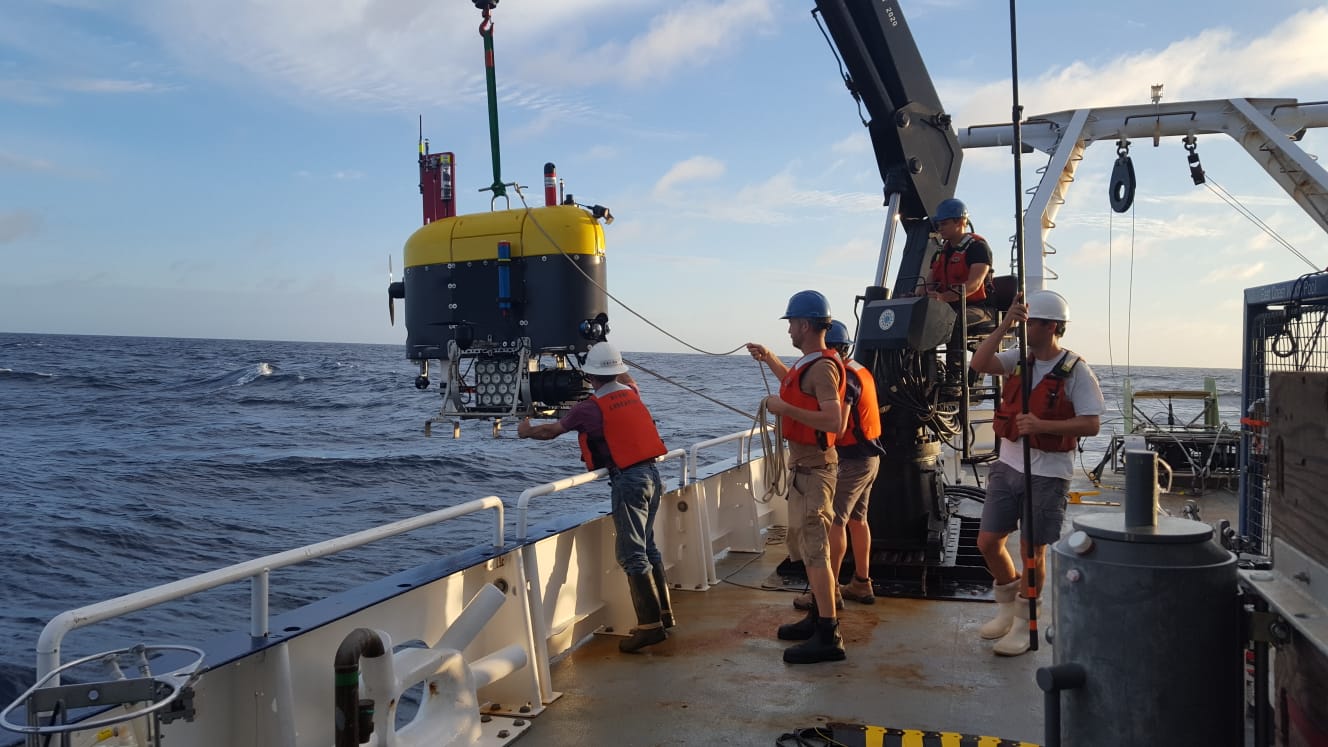

Getting Mesobot ready for a dip in the water is no easy feat. Designed to follow a single organism for the duration of its nightly migration, it requires a suite of motors, thrusters, a complex of electronics, and perhaps most importantly, intelligence--artificial intelligence--to read and respond to its environment. Orchestrating all of these mechanisms at once is made even more complex by the fact that they all have to operate simultaneously under extreme pressure in electrically conductive saltwater. That’s why it’s critical to test, retest and test Mesobot again and again long before it ever gets its first taste of ocean. In order to do that, OTZ engineers deconstructed it to work with all its components individually.

While they’re at it, you can take a peek inside with today's slideshow (below).

—Jennie Berglund, OTZ Field Correspondent